Yas zaj duab xis raws li cov khoom siv luam ntawv, nws yog luam tawm raws li lub hnab ntim khoom, nrog lub teeb thiab pob tshab, ya raws thiab oxygen tsis kam, huab cua zoo nruj, tawv thiab folding tsis kam, du nto, tuaj yeem tiv thaiv cov khoom, thiab tuaj yeem tsim cov duab zoo nkauj. khoom, xim thiab lwm yam zoo. Nrog rau kev loj hlob ntawm petrochemical kev lag luam, ntau thiab ntau ntau yam ntawm yas zaj duab xis, feem ntau siv yas zaj duab xis polyethylene (PE), polyvinyl chloride (PVC), polystyrene (PS), polyester zaj duab xis (PET), polypropylene (PP), nylon (PA) thiab lwm yam. Tsis tas li ntawd, muaj ntau ntau hom yas zaj duab xis, cov kws tshaj lij kev lag luam ntim khoom lag luam Shunfa packing xav tias yuav tsum nkag siab txog cov yam ntxwv ntawm cov yas zaj duab xis ua ntej cov hnab ntim khoom. Tshwj xeeb txheeb xyuas cov yam ntxwv ntawm 11 hom yas zaj duab xis hauv qab lub hnab ntim rau koj siv.

1. Polyvinyl chloride (PVC)

Qhov zoo ntawm PVC zaj duab xis thiab PET yog zoo sib xws, thiab tib yam belongs rau cov yam ntxwv ntawm transparency, breathability, acid thiab alkali tsis kam. Ntau lub hnab ntim khoom noj thaum ntxov yog ua los ntawm PVC hnab. Txawm li cas los xij, PVC tuaj yeem tso cov carcinogens vim tsis tiav polymerization ntawm qee cov monomers hauv cov txheej txheem tsim khoom, yog li nws tsis tsim nyog rau kev sau cov khoom noj khoom haus, thiab ntau yam tau hloov mus rau PET ntim hnab, cim cov khoom cim npe yog No. 3.

2. Polystyrene (PS)

Kev nqus dej ntawm PS zaj duab xis yog tsawg, tab sis nws qhov kev ruaj ntseg zoo dua, thiab nws tuaj yeem ua tiav los ntawm kev tua tuag, nias tuag, extrusion thiab thermoforming. Feem ntau, nws tau muab faib ua foaming thiab unfoaming ob pawg raws li seb nws tau dhau los ntawm cov txheej txheem foaming. Unfoamed PS feem ntau yog siv rau hauv cov khoom siv hauv tsev, cov khoom ua si, cov ntawv sau, thiab lwm yam, thiab tseem tuaj yeem ua rau hauv cov thawv ntim nrog cov khoom noj siv mis fermented, thiab lwm yam. Nyob rau hauv xyoo tas los no, nws kuj tau siv dav hauv kev ua cov tais diav pov tseg, thiab cov khoom siv cim. yog No.6.

3. Polypropylene (PP)

Ordinary PP zaj duab xis txais yuav tshuab moulding, txheej txheem yooj yim thiab tus nqi qis, tab sis qhov kev ua haujlwm kho qhov muag yog me ntsis qis dua CPP thiab BOPP. Qhov loj tshaj plaws ntawm PP yog qhov kub thiab txias tsis kam (kwv yees li -20 ° C ~ 120 ° C), thiab melting point yog siab li 167 ° C, uas yog tsim rau sau cov kua mis, mis nyuj thiab lwm yam khoom uas xav tau kev tua kab mob. . Nws qhov hardness siab dua PE, uas yog siv los tsim cov thawv ntim khoom, thiab cov khoom siv lub cim yog No. 5. Feem ntau hais lus, PP muaj qhov nyuaj dua, thiab qhov saum npoo yog ci dua, thiab tsis tsim cov ntxhiab tsw ntxhiab thaum hlawv, thaum PE muaj tswm ciab hnyav dua.

4. Polyester Zaj duab xis (PET)

Polyester zaj duab xis (PET) yog thermoplastic engineering yas. Cov ntaub ntawv nyias nyias ua los ntawm cov ntawv tuab los ntawm txoj kev extrusion thiab bidirectional stretching. Polyester zaj duab xis yog tus cwj pwm los ntawm cov khoom siv zoo heev, siab rigidity, hardness thiab toughness, puncture kuj, kev sib txhuam tsis kam, siab thiab kub tsis kam, tshuaj tsis kam, roj kuj, huab cua nruj thiab zoo tshuaj tsw qab, yog ib qho ntawm feem ntau siv permeability kuj sib xyaw. zaj duab xis substrates, tab sis corona kuj tsis zoo, tus nqi yog siab. Lub thickness ntawm zaj duab xis yog feem ntau 0.12 hli, uas yog feem ntau yog siv los ua cov khoom siv sab nrauv ntawm lub hnab ntim khoom noj khoom haus, thiab cov ntawv luam tawm tau zoo. Kos cov khoom cim 1 hauv cov khoom yas.

5. Nylon (PA)

Nylon yas zaj duab xis (polyamide PA) yog tam sim no industrialized zus tau tej cov ntau yam, ntawm uas lub ntsiab ntau yam siv los tsim zaj duab xis yog nylon 6, nylon 12, nylon 66 thiab hais txog. Nylon zaj duab xis yog ib zaj duab xis tawv heev, zoo pob tshab, thiab muaj luster zoo. Lub zog tensile, tensile lub zog, siab thiab tsis kub tsis kam, roj kuj, organic hnyav tsis kam, hnav tsis kam thiab puncture kuj zoo heev, thiab cov yeeb yaj kiab kuj yog mos, zoo heev oxygen tsis kam, tab sis dej vapor barrier tsis zoo, noo noo nqus, noo noo permeability yog loj, thiab tshav kub sealing tsis zoo. Haum rau ntim cov khoom tawv, xws li cov khoom noj roj, cov zaub mov kib, cov khoom ntim khoom noj, cov zaub mov ua noj, thiab lwm yam.

6. High Density Polyethylene (HDPE)

HDPE zaj duab xis yog hu ua geomembrane lossis impermeable zaj duab xis. Nws melting point yog hais txog 110 ℃ -130 ℃, thiab nws cov txheeb ze ntom ntom yog 0.918-0.965kg / cm3. Yog lub siab crystallinity, tsis yog-polar thermoplastic resin, thawj HDPE tsos yog milky dawb, nyob rau hauv ib tug me me cross-section ntawm ib co degree ntawm translucent. Nws muaj kev tiv thaiv zoo rau qhov kub thiab txias thiab cuam tshuam, txawm tias nyob rau ntawm -40F tsis kub. Nws cov tshuaj stability, rigidity, toughness, txhua yam muaj zog, tsim kua muag zog zog yog zoo heev, thiab nrog rau kev nce ntawm ceev, mechanical zog, barrier zog, tensile zog thiab tshav kub kuj yuav raug txhim kho raws li, muaj peev xwm tiv taus acid, alkali, organic solvents thiab lwm yam. corrosion. Kev txheeb xyuas: feem ntau opaque, xav tias zoo li siv quav ciab, hnab yas rub los yog txhuam thaum rustling.

7. Low Density Polyethylene (LDPE)

LDPE Zaj Duab Xis Ceev yog tsawg, mos, tsis kam ua tshuaj lom zem, yog muaj zog oxidizing acid), alkali, rwb thaiv hluav taws xob zoo. LDPE feem ntau yog siv rau hauv cov hnab yas, kos cov cim cov khoom siv yog No. 4, thiab nws cov khoom siv feem ntau yog siv hauv kev tsim vaj tsev thiab kev ua liaj ua teb, xws li geomemofilm, zaj duab xis ua liaj ua teb (tso zaj duab xis, mulch film, cia zaj duab xis, thiab lwm yam). Kev txheeb xyuas: Lub hnab yas ua los ntawm LDPE yog softer, tsis tshua muaj rustling thaum kneading, txheej ntim yas zaj duab xis yog mos thiab yooj yim los rhuav LDPE, thiab ntau nkig thiab tawv yog PVC los yog PP zaj duab xis.

8. Polyvinyl cawv (PVA)

Polyvinyl cawv (PVA) siab barrier composite zaj duab xis yog ib zaj duab xis nrog siab barrier khoom tsim los ntawm txheej txheej hloov dej-soluble kua ntawm polyvinyl cawv ntawm substrate ntawm polyethylene yas. Vim hais tias lub siab barrier composite zaj duab xis ntawm polyvinyl cawv muaj zoo barrier zog thiab ua tau raws li qhov yuav tsum tau ntawm kev tiv thaiv ib puag ncig, kev lag luam zeem muag ntawm cov khoom ntim no yog ci heev, thiab muaj kev lag luam dav hauv kev lag luam khoom noj.

9. Casting polypropylene zaj duab xis (CPP)

Casting polypropylene zaj duab xis (CPP) yog ib yam uas tsis yog-stretchable, tsis-oriented ca extrusion zaj duab xis uas ua los ntawm yaj casting quench txias. Nws yog tus cwj pwm los ntawm kev ceev ceev, siab yield, zaj duab xis transparency, gloss, barrier khoom, softness, thickness uniformity yog zoo, muaj peev xwm tiv taus kub kub ua noj (ua noj kub siab tshaj 120 ° C) thiab kub kub sealing (kub sealing kub tsawg dua. 125 ° C), qhov sib npaug ntawm kev ua haujlwm zoo heev. Kev ua haujlwm tom qab xws li luam ntawv, cov khoom sib xyaw yog yooj yim, siv dav hauv textiles, khoom noj khoom haus, ntim khoom siv txhua hnub, ua cov khoom ntim sab hauv ntawm cov khoom ntim sib xyaw, tuaj yeem txuas lub txee lub neej ntawm cov khoom noj, ua kom zoo nkauj.

10. Bidirectional polypropylene zaj duab xis (BOPP)

Biaxial polypropylene zaj duab xis (BOPP) yog cov khoom ntim pob tshab uas tau tsim nyob rau xyoo 1960, uas yog cov kab ntau lawm tshwj xeeb los sib xyaw cov khoom siv polypropylene thiab cov khoom siv ntxiv, yaj thiab sib tov, ua cov ntawv, thiab tom qab ntawd ua ib zaj duab xis los ntawm kev ncab. Zaj yeeb yaj kiab no tsis tsuas yog muaj qhov zoo ntawm kev ceev, corrosion tsis kam thiab cov tshuab luam ntawv muaj zog, thiab tuaj yeem ua ke nrog daim ntawv, PET thiab lwm yam substrate. Nrog siab txhais thiab gloss, zoo heev number case nqus thiab txheej adhesion, siab tensile zog, zoo heev roj barrier zog, tsis tshua muaj electrostatic yam ntxwv.

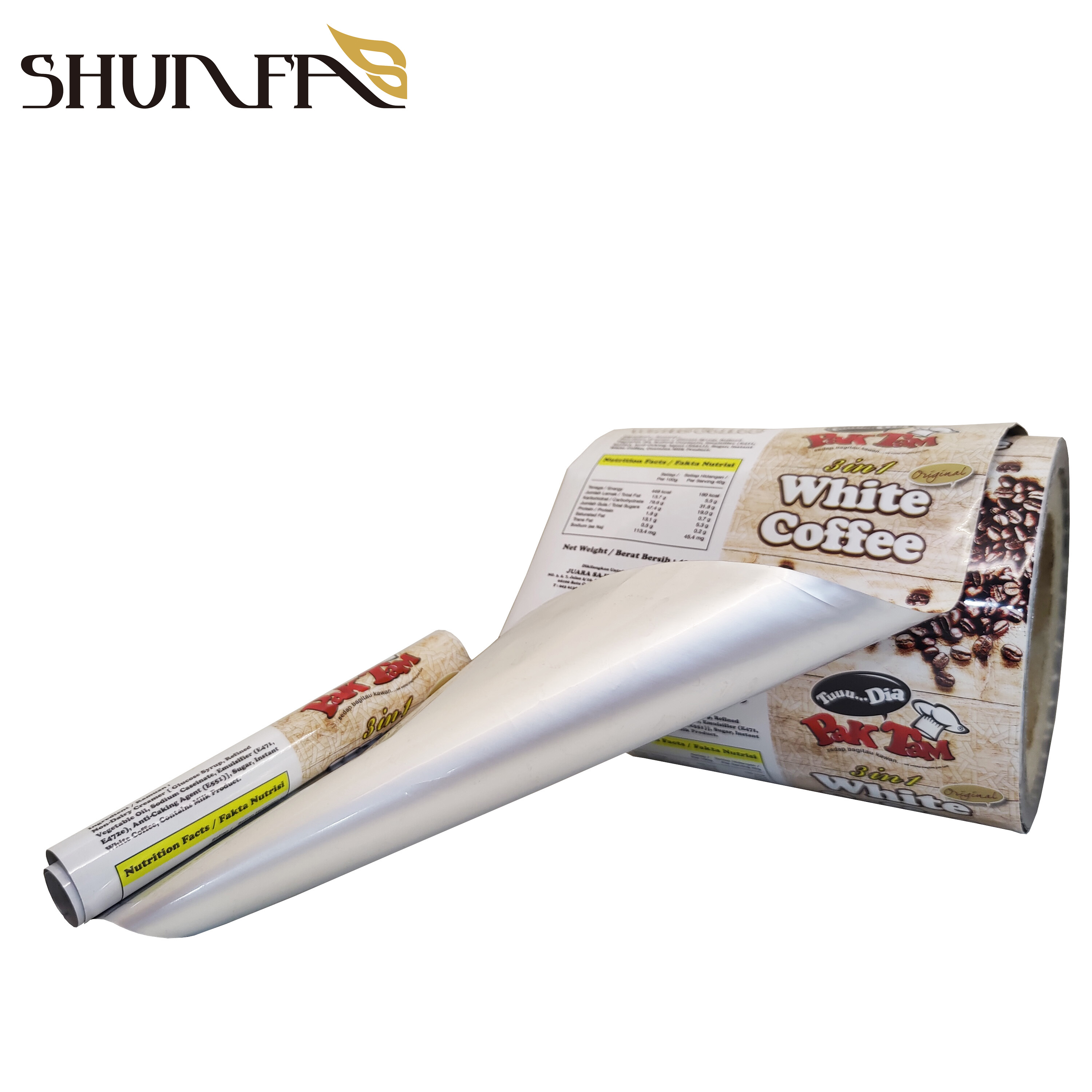

11. Metalized zaj duab xis

Metalized zaj duab xis muaj cov yam ntxwv ntawm ob qho tib si yas zaj duab xis thiab hlau. Lub luag hauj lwm ntawm aluminium plating rau saum npoo ntawm zaj duab xis yog los thaiv lub teeb thiab tiv thaiv ultraviolet hluav taws xob, uas txuas ntxiv lub neej txee ntawm cov ntsiab lus thiab txhim kho qhov ci ci ntawm cov yeeb yaj kiab, hloov cov ntawv ci txhuas rau qee qhov, thiab tseem muaj pheej yig, zoo nkauj thiab zoo barrier zog. Yog li ntawd, metalized zaj duab xis yog dav siv nyob rau hauv composite ntim, feem ntau yog siv nyob rau hauv biscuits thiab lwm yam qhuav, puffed zaub mov ntim, tshuaj thiab tshuaj pleev ib ce ntim.

Post lub sij hawm: Lub Xya hli ntuj-19-2023